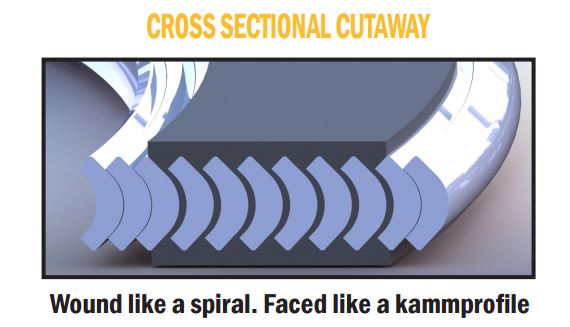

Flexitallic invented the spiral wound gasket in 1912, there was nothing like it. 100 years later, They introduced the Change gasket-an incredibly resilient metal-wound gasket that’s designed to deliver the most dynamic seal ever. Today there are thousands of Change gaskets in service. Change is manufactured with proprietary equipment, using a 5 X thicker metal spiral and a unique laser welding process that penetrates completely through the winding so it requires no inner or outer ring. Best of all, it’s proven to perform without fail at least 60% longer than any other gaskets, CGI Spiral Wound, Double Jacketed, CMG, or Kammprofile.

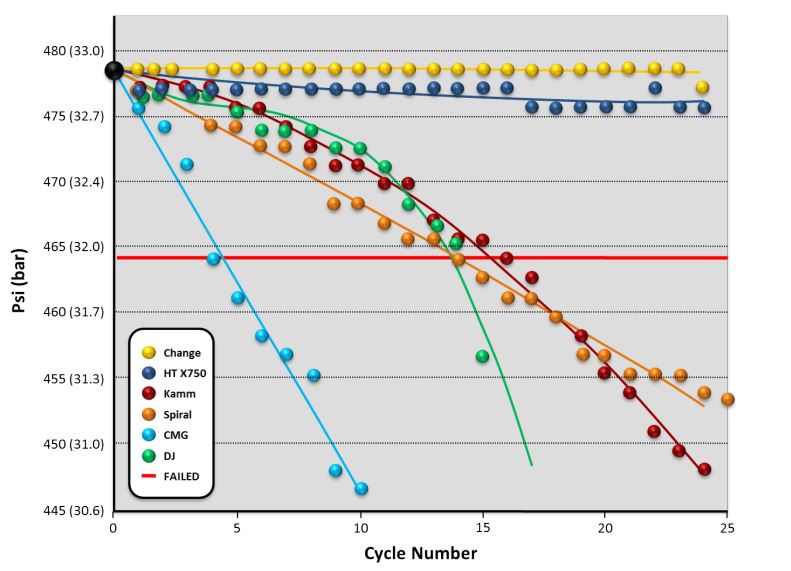

Thermal cycle test

Across a 24-day, 24-cycle pressure vs thermal cycle test at 608°F (302º C ) replicating industry application conditions, the Change gasket lost just 1.5 PSI. total, never coming close to the failure point.

- 4” Class 300, RF, B16 studs •

- Thermal Cycle Phase – Purge and Heat up to 608°F (302°C) at 3.5°F/min

- Pressurize to 480 psi

- Hold 1 hr

- Unassisted Cooling to Ambient

- Repeat 24 times unless gross failure occurs – Approximately 24 hours per cycle •

- Record pressure drop every cycle •

- Max allowable P drop: 14.5 psi

Change Gasket Summary

- Construction is more robust than a Spiral and Kammprofile

- Compression is more consistent than a Spiral and Kammprofile

- Creep is VERY low

- Recovery is VERY high

- Seals with exceptional tightness, especially thermal cycles

- Crush resistant; no inner ring/compression stop required

- Fits most – if not all – flange arrangements •

- Available in all industrial metals